Industrial facilities rely on storage tanks every day. Whether the tank holds water, chemicals, petroleum products, food ingredients, or wastewater, the right coating system is what keeps the tank safe, compliant, and long lasting. Understanding the difference between interior and exterior coating systems is essential when planning any maintenance or restoration project. Although both applications fall under the broader category of industrial tank coatings, the conditions they face and the performance requirements they must meet can be completely different.

At M&M Tank Coating Company, clients often ask why interior coatings matter so much, or why exterior coatings require additional protection. The truth is that both environments pose unique challenges. Choosing the right system can prevent corrosion, reduce downtime, and extend the service life of the tank for many years.

The Role of Environment in Coating Selection

Environment is the first major factor that separates interior coatings from exterior coatings. Interior surfaces are in direct contact with stored materials, which may be corrosive or sensitive to contamination. Exterior surfaces face sunlight, moisture, temperature swings, and harsh weather. Both situations require high performing industrial tank coatings, but the formulation and durability required for each environment differ significantly.

Interior Tank Coatings: Protection from Within

Interior coatings are engineered to protect the tank from the product it holds. This means the coating must be compatible with the stored material, whether it is potable water, chemicals, fuels, or food grade products. It must also prevent the stored material from interacting with the steel or concrete substrate.

Key considerations for interior coatings include:

Chemical resistance:

If the tank holds acidic or alkaline materials, the interior coating must be able to withstand repeated exposure without softening or blistering.

Product purity:

For potable water or food grade applications, the coating must meet strict safety standards. Industrial tank coatings in these environments often require NSF, FDA, or other compliance certifications.

Cleanability:

Smooth, uniform coating surfaces make inspections easier and reduce microbial growth.

Long term corrosion control:

Interior corrosion can be hidden until the damage becomes expensive or dangerous. Specialized industrial tank coatings help prevent pitting, rust, and structural failures.

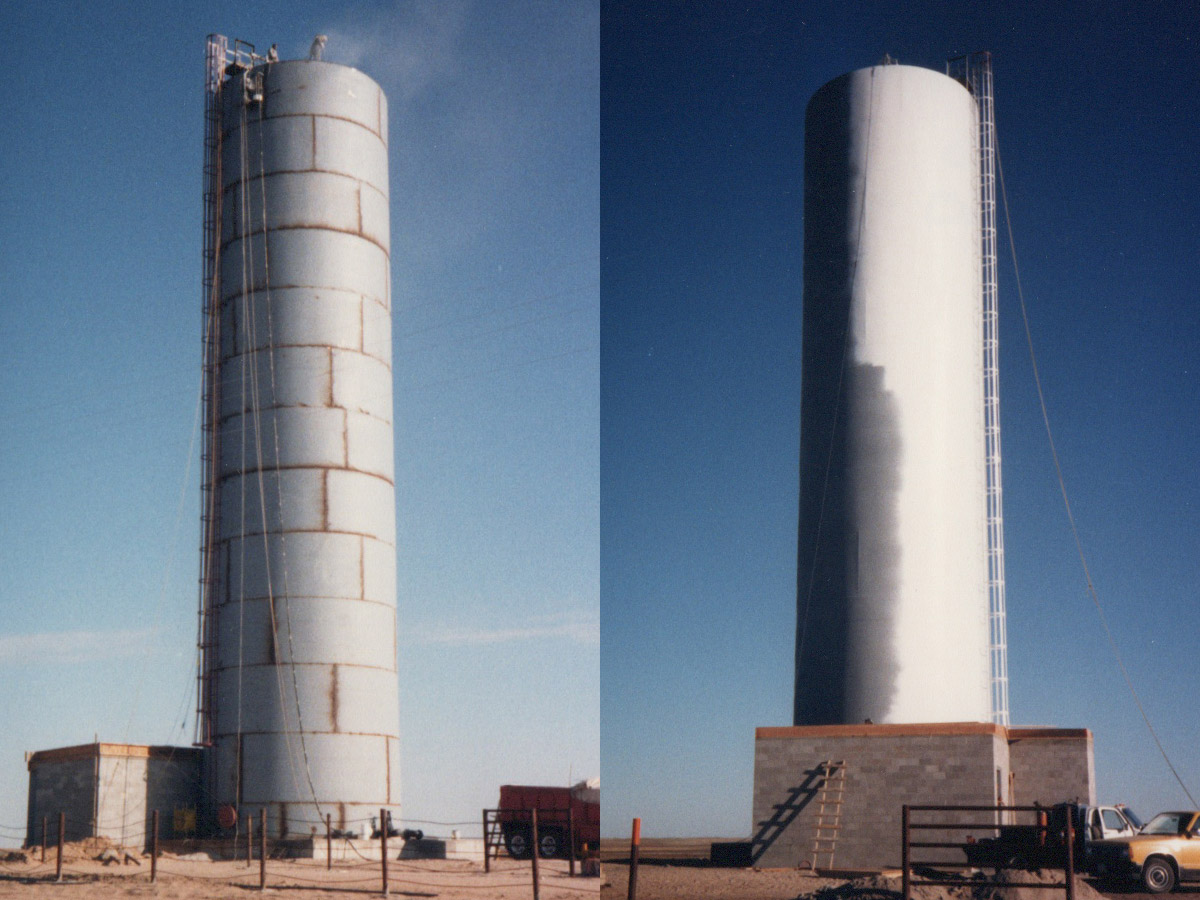

Exterior Tank Coatings: Weather, Wear, and UV Exposure

Exterior tank coatings must defend against a completely different set of challenges. Sun exposure, freeze and thaw cycles, wind, rain, and temperature extremes all impact the coating’s performance. Unlike controlled interior conditions, exterior surfaces endure constant environmental change.

Key considerations for exterior coatings include:

UV resistance:

Sunlight can cause fading, chalking, and degradation of coatings. Exterior industrial tank coatings are formulated to maintain color stability and prevent surface breakdown.

Moisture protection:

Rain, snow, humidity, and condensation can accelerate corrosion on exposed steel. High performance coatings provide a moisture barrier.

Thermal movement:

Temperature changes cause the tank to expand and contract. Exterior coatings must be flexible enough to move with the structure without cracking.

Aesthetic and branding needs:

Many facilities want tanks to reflect their company identity. Exterior coatings can be tailored for color, gloss, and long term appearance.

Access, Safety, and Downtime Considerations

Both interior and exterior coating projects require careful planning, but the logistics differ significantly. Interior work often involves confined space entry, strict ventilation requirements, product removal, and specialized safety protocols. Exterior work requires aerial lifts, fall protection, and attention to weather conditions.

Access challenges:

Interior tanks may require manway entry, scaffolding, or specialized equipment. Exterior tanks may require coating teams to work at height. M&M Tank Coating Company helps clients plan safe, efficient access for both situations.

Safety requirements:

Confined space safety, respiratory protection, and chemical handling are all part of interior work. Exterior work may involve wind exposure, equipment positioning, and surface preparation controls.

Downtime planning:

Interior projects usually require a full shutdown and cleaning of the tank. Exterior projects may be scheduled seasonally to avoid weather interruptions. A provider experienced in industrial tank coatings will help clients minimize downtime and avoid unnecessary operational delays.

Choosing the Right Coating Partner

Selecting the correct coating system is only part of the equation. The team applying the coating must properly assess the environment, surface conditions, and performance needs. High quality industrial tank coatings depend on expert surface preparation, application precision, and dependable curing conditions. A trusted partner like M&M Tank Coating Company ensures that both interior and exterior systems are installed correctly and tailored to the tank’s operational demands.

Making the Right Coating Choice

Interior and exterior tank coatings may share the same purpose, but the environments they must withstand are very different. Understanding the unique requirements of each application helps facility managers choose the right solution, reduce long term maintenance costs, and protect critical assets. With expertise in both interior and exterior industrial tank coatings, M&M Tank Coating Company is committed to delivering reliable protection and long lasting performance for every project.

M&M Tank Coating Company

M&M Tank Coating Company